Education

A Look at CPQ in the Manufacturing Industry

Published

3 years agoon

By

techonpcThe manufacturing industry isn’t for the faint of heart by any stretch of the imagination. There as many moving parts in the company as there are in the machines that your company uses––and for the sake of your company, you need the parts to move synergistically. As you know, efficiency is the name of the game in the manufacturing industry.

There’s nothing more frustrating to a manufacturer than when nothing lines up properly and small issues become potential catastrophes. Like most issues in today’s fast-paced world, there’s a software solution to help fabricators get a wrangle on their business operations, and it’s called configure-price-quote (CPQ) software. Continue reading to learn more about how CPQ software can help your company reach new heights.

CPQ promotes uniformity of products and raw materials.

CPQ software helps manufacturers to ensure that they have the ability to customize solutions for their customers’ needs. Could you imagine buying rims for your car only to realize that they don’t properly fit your vehicle?

For the sake of example, let’s assume the car has custom rims, which means it needs a special type of tires on them. In addition to the tires, depending on the size of the rims, you might have to raise the car frame a few inches with a lift kit or cut the wheel wells to keep the tires from scraping the fender. Being that custom rims are usually larger and heavier than factory rims, you may even need a more powerful transmission and/or motor for your car to run the same as it did without the rims.

With CPQ software, it’s easier to figure out what additional changes a small adjustment may facilitate. When you know how a small adjustment will affect the product as a whole, it’s easier to ensure the quality of your products.

Configure.

One of the biggest trends in manufacturing is customization. Customers want products that meet their specific needs or wants, and they’re willing to look for distributors who can meet the demand. The issue with customizing complex products is that one small adjustment usually leads to a series of more changes to the product for the sake of functionality.

CPQ software allows fabricators to forecast the changes that will need to be made during the manufacturing process in order to deliver the custom product that the customer wants. When making custom-configured complex products, you might have to adjust everything from your drilling milling machine to your CNC cutter to meet the specifications. However, CPQ 3D modeling of the product eliminates guesswork by showing you what the finished product will look like and telling you what tools and materials you’ll need.

Configure One is one of the top CPQ software vendors. Their technology is affordable and will help you greatly reduce the time it takes to make changes to the design of a complex product. CPQ technology is essential for any company that wants to make custom configured products for their customers.

Price and quote.

Price and quote

It only stands to reason to assume that if the make of a product is changed, the price will also. One of the most difficult parts of customizing a mass-produced product is figuring out how much to alter. Having Configure One’s CPQ software is like having the world’s best project manager. CPQ tools like Configure One help you figure out how much more your materials will cost for the configured product, as well as how many more man-hours will have to go into the production of the product.

With CPQ systems, your sales rep can give customers a much more accurate idea of what their customization needs will cost them. The more simple and straightforward your pricing is, the better your company and sales reps look to potential clients. No one wants to feel like they’re being tricked during the billing process. However, the more you know, the more transparent you can be with your customers, and that’s where CPQ comes into play.

In a world where everyone wants custom solutions, CPQ tools can be a fabricator’s best friend. From product design and configuration to pricing, CPQ does the hard part for you.

Follow Me

Unleashing the Power of the Office Accelerator: Maximizing Productivity and Efficiency in the Workplace with Office 365 Accelerator

Unlocking the Hidden Potential of Your Website: Strategies for Growth

From AI to VR: How Cutting-Edge Tech Is Reshaping Personal Injury Law in Chicago

Trending

Microsoft4 years ago

Microsoft4 years agoMicrosoft Office 2016 Torrent With Product Keys (Free Download)

Torrent4 years ago

Torrent4 years agoLes 15 Meilleurs Sites De Téléchargement Direct De Films 2020

Money4 years ago

Money4 years ago25 Ways To Make Money Online

Torrent4 years ago

Torrent4 years agoFL Studio 12 Crack Télécharger la version complète fissurée 2020

Education3 years ago

Education3 years agoSignificado Dos Emojis Usado no WhatsApp

Technology4 years ago

Technology4 years agoAvantages d’acheter FL Studio 12

Technology4 years ago

Technology4 years agoDESKRIPSI DAN MANFAAT KURSUS PELATIHAN COREL DRAW

Education3 years ago

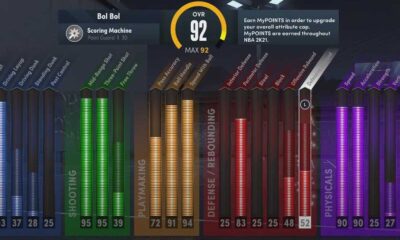

Education3 years agoBest Steph Curry NBA 2K21 Build – How To Make Attribute, Badges and Animation On Steph Curry Build 2K21

You must be logged in to post a comment Login