Education

Industrial Barcode Printers and Barcode Printer Ribbons

Published

4 months agoon

By

techonpc

Barcode

Organizing industrial production involves details of various kinds, so there are lots of things to consider. One of those is to select the right industrial barcode printer and take care of its maintenance. It includes both technical components as well as thermal transfer ribbons, RFID tags, and other necessary materials for its uninterrupted work.

In this article, we focus on industrial barcode printers and explain why they are necessary for production. Also, we particularly explore wax and resin ribbons for such printers. You will find all the necessary information about each thermal transfer ribbon type and decide which ones are the most suitable for your production and how to get them.

Industrial Barcode Printers

One of the fundamental processes in each production facility refers to barcode printing. For that, there are specially designed printers that cope with the task of label management in different ways.

As barcodes are required literally for every physical product, an industrial barcode printer is an inevitable part of any factory. However, barcode printers are also used in warehouses, shipping centers, and other establishments.

One of the most popular companies manufacturing industrial barcode printers is called Zebra. It works with different kinds of ribbons and RFID tags for designing and applying barcodes. Consider Zebra Industrial Wax Thermal Transfer Ribbons for your production line.

Thermal Transfer Ribbons for Industrial Printers

Let’s have a look at different types of barcode ribbons that are used together with industrial barcode printers. Those are usually thermal transfer ribbons used in thermal printers for transferring barcodes, expiration dates, product logos, and other similar data to thermal labels.

The technology of thermal transfer printing functions in the following way – a hot printhead heats up the ribbon material and applies it on some surface. It is compatible with a variety of materials, which makes this approach suitable for many use cases.

Below, we present the most common types of thermal transfer ribbons: wax ribbons, wax resin ribbons, and resin ribbons. Each of them would be suitable depending on the further exploitation of a particular product. Note that selecting the right ribbon types not only determines the barcode lifecycle but also influences the operational capacity of the printhead over time.

Wax Ribbons

The most cost-effective option for industrial barcode printing is the implementation of wax ribbons for label printing. Such ribbons are characterized by a rather low price compared to others and high effectiveness at the same time.

The popularity of wax ribbons is not only influenced by the pricing but also by the sphere of its application. Such thermal transfer ribbons could be applied practically on any product easily. Make sure that your printer supports wax printing before buying these ribbons.

It’s necessary to add a note about wax ribbons, as those are not resistant to all-year-round storage and travel conditions. They cannot resist extremely high and low temperatures, direct sun rays, and extreme weather anomalies. Thus, if your product is supposed to be exposed to such circumstances, wax ribbons might not be the best solution for that.

Wax Resin Ribbons

Another type of ribbons refers to the mix of wax and resin materials, which still keep them flexible but more resistant to sun, water, chemicals, and so on. Wax resin ribbons also stay safe even after mechanical disturbances such as rubbing or smearing. The colors don’t vanish or get blurred if any kind of such physical event has taken place.

Better protection levels for printed labels with wax resin ribbons naturally result in higher costs than those of wax solutions. The price for them is at least two times higher than for wax ribbons.

When thinking of whether wax resin ribbons would be applicable to you, think of how your product would travel and be stored further. If some extreme weather or transportation conditions are possible, take this kind of ribbons with no doubt.

Resin Ribbons

The toughest item in the collection of thermal transfer ribbons stands for resin ribbons. At the same time, those are also the most expensive solutions for industrial manufacturing. It’s so because there is a range of benefits behind resin ribbons.

The first and most significant advantage of resin ribbons is that they are resistant to practically everything. Direct sun rays, heat, extremely low temperatures, chemicals, and other liquid substances have no or minimum impact on them. Thus, labels created with resin ribbons would particularly suit products aimed to be stored at low or high temperatures, such as frozen products. Moreover, resin ribbons are good to be applied to synthetic materials such as clothing labels.

Make sure your printer is equipped with all the necessary mechanisms to use resin ribbons for production. Usually, those are printers that can work at very low speeds.

Evaluation Criteria

Before buying the supply material for your printer, you need to check several things. The first and most important one is the compatibility of your printer with various thermal transfer ribbon types. This information can be found either in the documentation provided together with your printer shipment or on the official website of the printer manufacturer or provider.

Another important criterion refers to the industry your company operates within. If you produce electronic components for technical details, make sure that they are temperature-resistant. In that case, using resin ribbon would be the most applicable solution. If you manufacture some kind of pharmaceutical product, wax resin ribbon would be enough.

Traveling conditions also have a great impact on the selection of the thermal transfer ribbon type. In case your products are supposed to travel certain distances to reach the point of destination or ship overseas, the quality and readability of the label must be preserved in a decent condition.

The same goes for the shipping and transportation companies. If, for example, a logistics company operates in a mild climate zone with average temperatures, wax ribbons would be enough for printing. In case of harsh weather conditions, expect cargo on its way to destination points, then wax resin or simply resin ribbons might be the perfect choice.

Follow Me

Unleashing the Power of the Office Accelerator: Maximizing Productivity and Efficiency in the Workplace with Office 365 Accelerator

Unlocking the Hidden Potential of Your Website: Strategies for Growth

From AI to VR: How Cutting-Edge Tech Is Reshaping Personal Injury Law in Chicago

Trending

Microsoft4 years ago

Microsoft4 years agoMicrosoft Office 2016 Torrent With Product Keys (Free Download)

Torrent4 years ago

Torrent4 years agoLes 15 Meilleurs Sites De Téléchargement Direct De Films 2020

Money4 years ago

Money4 years ago25 Ways To Make Money Online

Torrent4 years ago

Torrent4 years agoFL Studio 12 Crack Télécharger la version complète fissurée 2020

Education3 years ago

Education3 years agoSignificado Dos Emojis Usado no WhatsApp

Technology4 years ago

Technology4 years agoAvantages d’acheter FL Studio 12

Technology4 years ago

Technology4 years agoDESKRIPSI DAN MANFAAT KURSUS PELATIHAN COREL DRAW

Education3 years ago

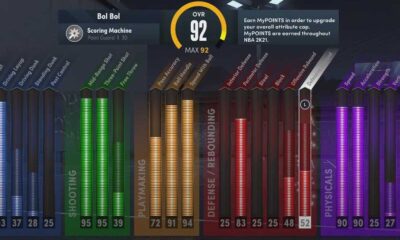

Education3 years agoBest Steph Curry NBA 2K21 Build – How To Make Attribute, Badges and Animation On Steph Curry Build 2K21

You must be logged in to post a comment Login